MEASURES AND ANALYSIS EQUIPMENT

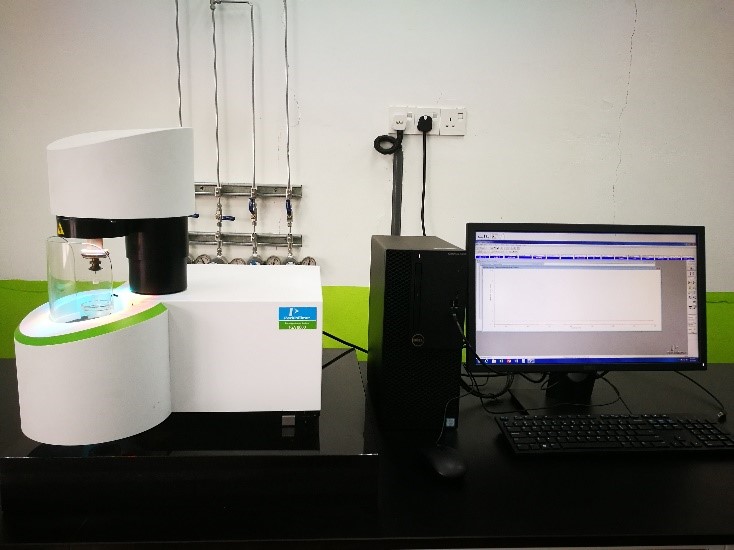

1. Thermogravimetric Analyzer – Test Method ISO 9924-1

TGA is widely used for the purpose of material characterization and weight percentage analysis of organic volatiles, carbon black and filler in a rubber compound, with a function of increasing temperature, or isothermally as a function of time.

2. Moisture Analysis – Test Method ASTM C 566-97

This test is used primarily to determine the moisture content in our raw materials as part of our effort to monitor our raw material quality. Both polymers and carbon black are tested for their moisture content before they are used in production. Evaporable moisture in the sample is determined by drying, thus both surface and pore moisture of the sample can be determined

3. IRHD Hardness – Test Method ISO 48

A method to determine the hardness of vulcanized rubber on flat surfaces.The unit for this method is IRHD - International Rubber Hardness Degrees.

4.Total Dissolved Solid (TDS) meter and pH meter

To check the Total Dissolve Solid is an aggregate measurement of all the organic and inorganic material present in a sample of water. This includes dissolved organic compounds inorganic compounds, salts, minerals and ions in water.

pH meter for water is a tool that can be used to measure the acidity or alkalinity of a water sample.

5. Multiparameter Photometer with COD

This equipment is used for measuring key water and wastewater quality parameters. The cooling tower water quality such as Alkalinity, Total hardness, Total Dissolve Solid, Chloride and in total 40 key water quality parameter with different methods covering multiple ranges.

6. Flexometer Test – Test Method ISO 4666

Flexometer test with constant-strain amplitude is used to determine temperature rise and resistance to fatigue in vulcanized rubber. These properties of rubber can suggest possible predictions regarding durability of rubber in finished articles subject to dynamic flexing in service such as tyres, bearings, supports and cable-pulley insert rings.

7. Flex Cracking & Crack Growth Test – Test Method ISO 132

This test describes the method to determine the resistance of vulcanized or thermoplastic rubbers to the formation and growth of cracks, when subjected to repeat flexing on the De Mattia type machine.

8. Resilience Elasticity Test – Test Method ISO D4662

A fixed mass on a pendulum is used to deliver impact on to a flat piece of rubber to determine the rebound resilience of the rubber. The kinetic energy of the impacting mass is measured immediately before and after impact. The result provides an indication for energy loss through hysteresis. The percent rebound measured in the test is inversely proportional to hysteretic loss

9. Vertical Rebound Resilience Test – Test Method ASTM D2632

Impact resilience of solid rubber is determined from measurement of the vertical rebound of a dropped mass in this test. Resilience is a function of both dynamic modulus and internal friction of a rubber. Test data provides useful prediction for the behavior of rubber compound when it is subjected to impact.

10. High Speed Stirrer/Dispersers - Test Method ISO 22107:2021

To processes that disperse powders into a liquid continuous phase while reducing the size of agglomerates or flocs down to the intended level, that homogenize an existing dispersed solid phase of a suspension or the mixture of two suspensions, or that exchange the original continuous phase in a suspension for another

11. Overhead Stirrer - In House Lab Method

An overhead stirrer is a device found used for homogenizing, mixing, suspending, and recirculating high viscosity substances or large volumes.

12. Digital Microscope

Digital microscope with magnification range 24X to 162X to check the Carbon Black dispersion as per ASTM and ISO standard